3D Printed Red Nose Day Tags

/Tags Ready for printing

Red Nose Day is a UK charitable appeal. I do Lectures in Rhyme for it and all kinds of silly fun stuff. If you want to sponsor me for the next one you can do so here:

http://my.rednoseday.com/sponsor/robmiles

Last time we had a Red Nose Day I had some RFID tags that I used as the basis of a raffle. The holder of the winning tag won a rather nice Gadgeteer kit.

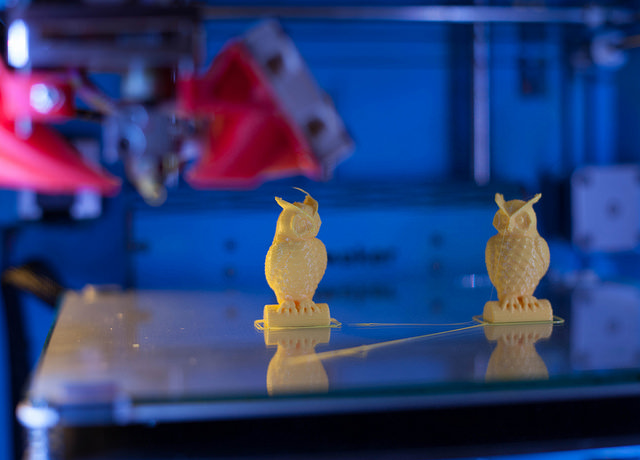

This year I thought I'd try something different. I thought I'd 3D print some tags and sell those instead. Each tag is completely unique thanks to a Python program that I've written that creates a combination of square and round layers of different sizes on the top of each one. Above you can see how this works. Each tag has five layers on top, of which two are square, the rest round. The square layers are rotated a random amount too so that there is plenty of variation.

I'm going to print only one of each tag design, except for the winners, where I'll print a "golden" tag as well. We'll draw out the golden tag at the lecture on Friday 13th and find the winner.

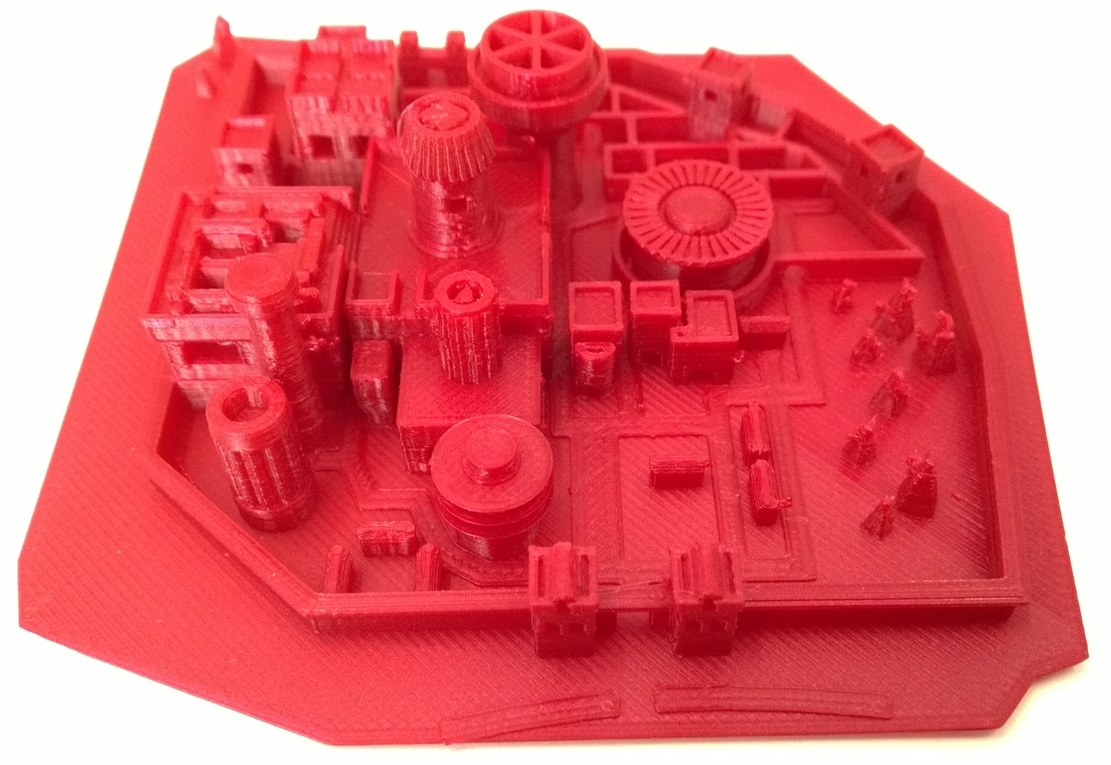

Printed tags. I'm going to do lots of different colours.

I'm quite intrigued by the idea of using software to produce 3D printed objects which are unique. This lets me explore the field in a good cause.

The tags will go on sale later this week at a two pounds each. You can do what you like with them, they'll come with a keyring attachment, but you could use them as unique earrings if you were so inclined. And the more you buy, the more chance you have of winning our top secret big prize.

Note: Sharp eyed readers might have noticed that some of the red tags above have more than two square layers. These are test ones that I produced while tweaking the code.