3D Printing at an angle

/Followers of my blog (yes, that’s both of you) will have been observing the fun and games I’ve been having trying to print a handle for my 3D printed camera. The problem is that if you print the handle vertically there is only a small surface in contact with the print bed. As the printing gets higher the print head becomes more and more likely to push the workpiece off the print bed. When it does you get a tree.

I tried printing with the handle flat on the print bed, but that caused other problems. There is a large open gap for the cable release that runs the length of the handle. This can’t be printed without extra support and the support material proved impossible to remove. I ended up with a handle that was solid all the way through So, in the end I tried something I’ve not done before. I tipped the whole workpiece by 45 degrees. This removed the need for any internal support.

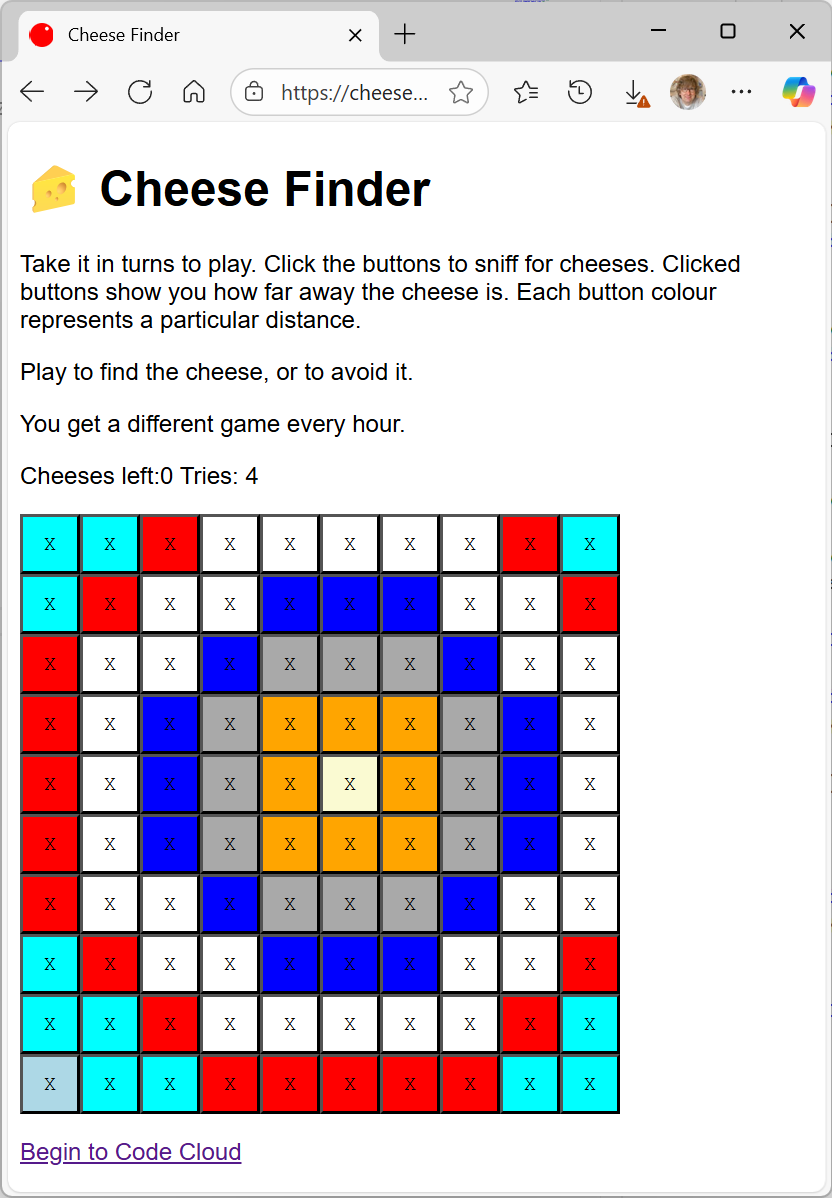

Above you can see how it works. The gap in the middle of the handle doesn’t need support and there is now a huge area of the workpiece in contact with the print bed so it grips really well. It worked a treat. The support came off very easily and left a surprisingly smooth finish all over the handle

If you’ve got something that needs internal support you might like to try the same thing. I used Cura to slice the model and the print preview (you can see it above) to check for any overhangs.

This might be a good technique for printing very small things, as it provides a larger base. It also removes any problems with the workpiece lifting up from the bed on the corners, which can be an issue when you try to print large objects.