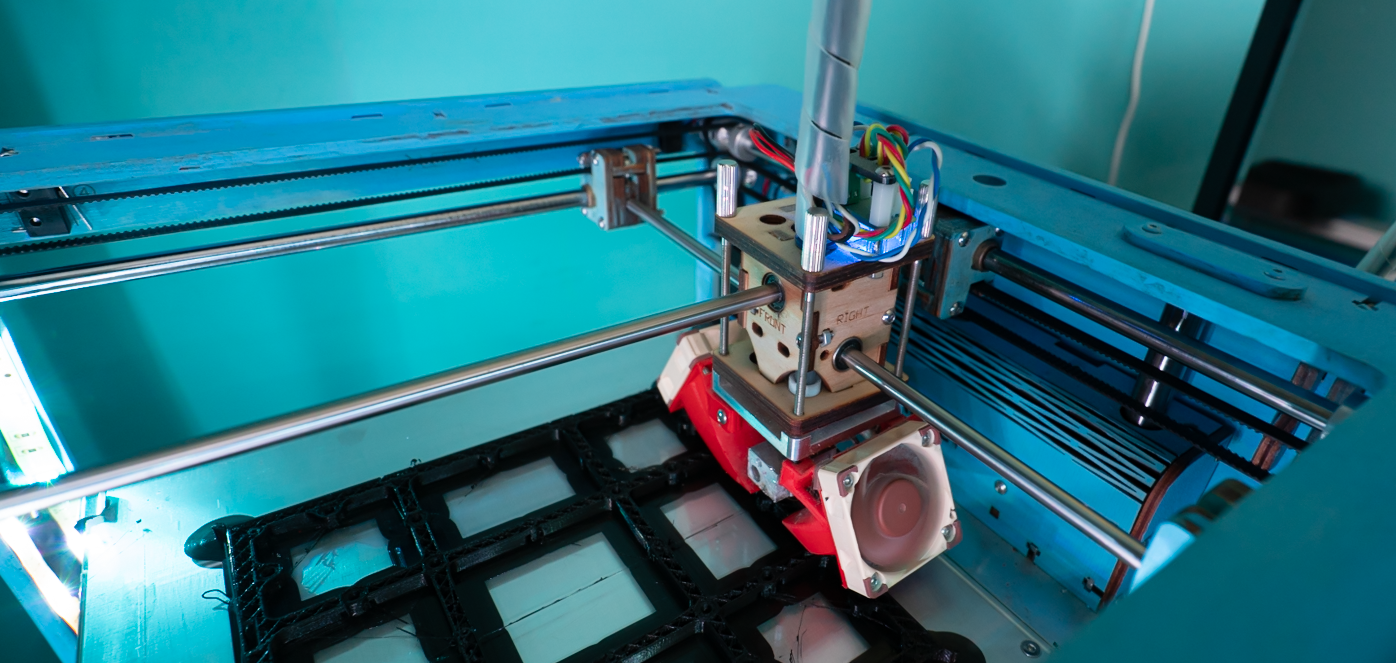

I mentioned on Sunday that I was a bit worried about the SD card reader on my lovely 3D printer being potentially unreliable. For years (seven actually) I’ve been writing my gcode files onto an SD card and then plugging into the printer for each print. This is probably not a good idea (and hasn’t been one for a while).

Anyhoo, a couple of failed prints on Sunday left me wondering about a better, and less physical, way of connecting the computer and the printer. I could just plug the printer straight into my computer, but I’ve never been keen on doing this. Knowing my luck the Windows 10 update process would steam in and break a print 8 hours in.

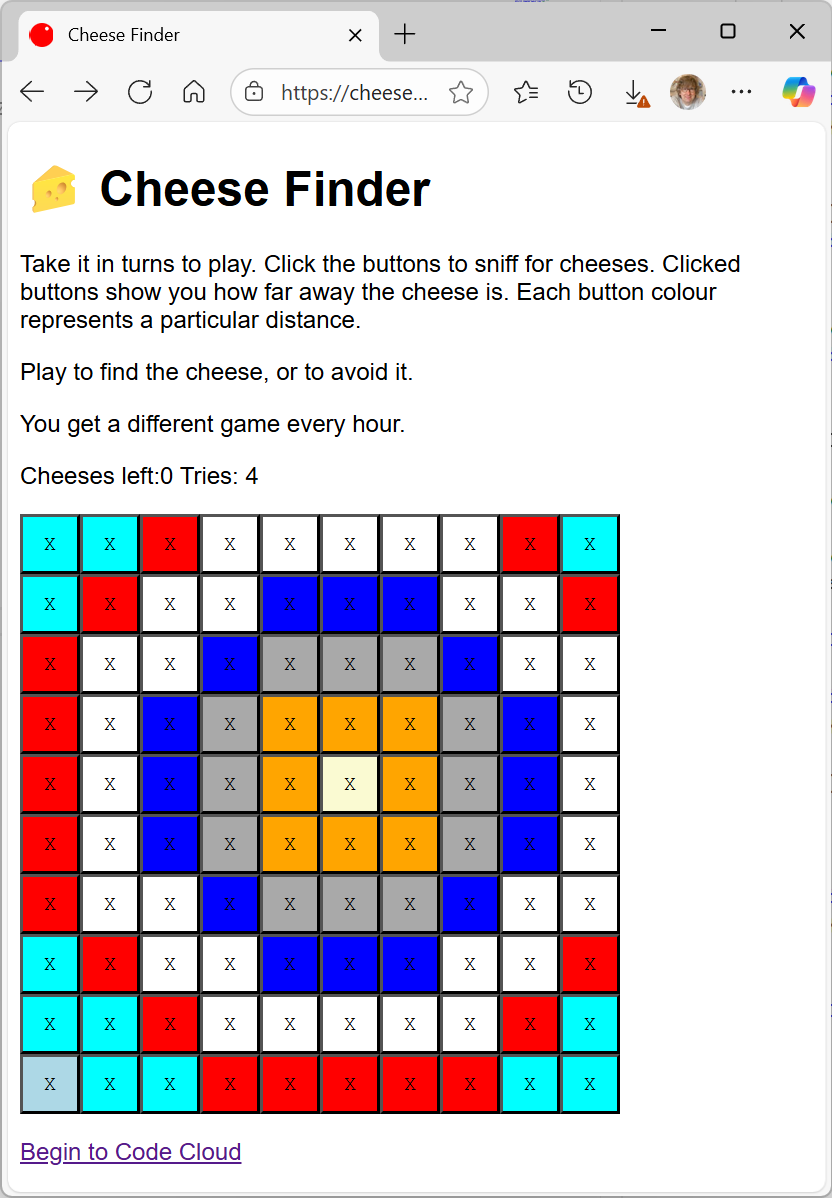

So today I took a proper look at Octoprint. Its a server that you attach to your printer. It gives you a lovely web interface that you can use to manage your prints and it also has a plugin for Cura, my favourite slicing tool so I can just open the files in Cura and then send them straight to the printer.

It’s wonderful. The installation is a breeze. There’s a boot image for Raspberry Pi that you just have to copy onto an SD card and you are in business. You don’t even have to attach a keyboard and screen to the Pi you are using a s server because you can do it all over SSL and via the browser.

I’ve done a couple of prints and they’ve worked very well. The next thing I’m going to do is attach a webcam to the server so that I can view print progress remotely.

If you have a 3D printer and a spare Raspberry Pi lying around you should definitely take a look at this.